-

KamilGreat quality, competitive price and outstanding communication.

KamilGreat quality, competitive price and outstanding communication. -

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs.

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs. -

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

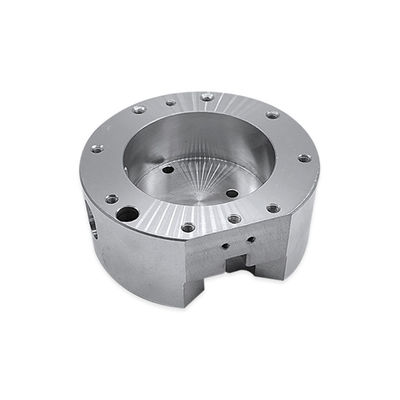

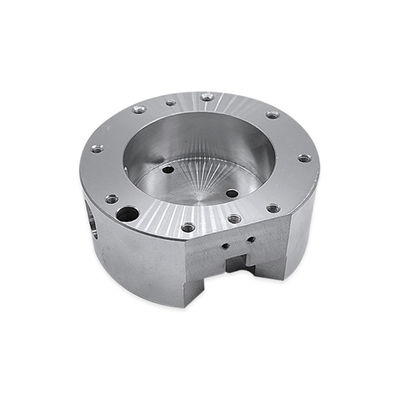

Precision Customized CNC Lathe Machining Part Services Steel Aluminum Titanium Machining Parts

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Micro Machining Or Not | Micro Machining | Type | Drilling,Turning,Other Machining Services,Broaching,Laser Machining |

|---|---|---|---|

| Material | Aluminum,Brass,Bronze,Stainless Steel,Customized | Service | Customized OEM,OEM/ODM/Customized/Design,cnc Machining Service,Drawing Working Accepted,OEM ODM |

| Surface Treatment | Anodize,anodizing,polishing Or Customized,Chrome Plating,no | Keyword | CNC Macining Parts,Precision Cnc Turning Machining |

| Sample | Available,Accept Sample Order | Finish | Colour Anodize,Power Coating,Nickel,Black Anodizing,Hot Dip Galvanized |

| Highlight | Aluminum CNC Lathe Machining Part,Titanium CNC Lathe Machining Part,Steel CNC Lathe Machining Part |

||

OEM Precision Customized CNC Lathe Machining Part Services Steel Aluminum Titanium Machining Parts

Attention: We are custom-made manufacturers of various parts according to customer requirements. The product pictures only show that we have the ability to produce similar products, and do not really sell this product.

For any new inquiries,please send us drawings,and tell us the part material,quantity and surface finish requirements for quotation by email as follow:

Ella

E-mail:ella.zhang@pusher-machinery.com

WhatsAPP: +8618262952513

What are the commonly used CNC machining Parts materials

![]()

![]()

Surface treatment

We have Full Suite of Professional Finishing Services . We make them better by applying a variety of treatments to improve their appearance, performance and durability. Contact us to learn more about our major finishing services .

![]()

Application

![]()

Quality Control

![]()

Product packaging

![]()

![]()

FAQ

Q: Is your organization committed to the concept of total quality management?

A: Yes, no matter whether in laser cutting, bending, or CNC machining, QC will conduct the first sample inspection and random inspection during the processing to ensure the quality of the products.