-

KamilGreat quality, competitive price and outstanding communication.

KamilGreat quality, competitive price and outstanding communication. -

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs.

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs. -

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

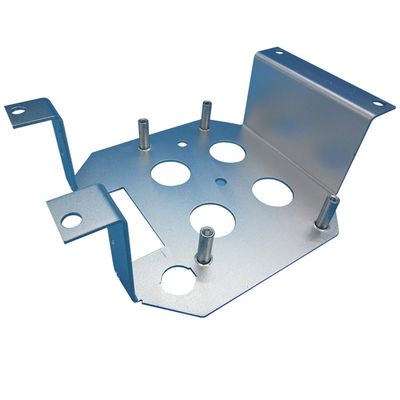

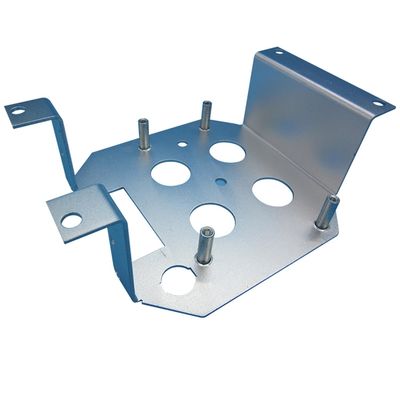

High Strength Stainless Steel Fabrication Parts Customized Bending And Welding

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminum, Stainless Steel, Copper, Bronze, Iron, Brass, Plastic | Size | Client's Drawings |

|---|---|---|---|

| Color | Customized Color | Process | Laser Cutting Bending Stamping |

| Surface Treatment | Painting\Powder Coating\Plating\Polishing | Type | OEM Sheet Metal Fabrication Parts |

| Highlight | high strength Steel Fabrication Parts,Stainless Steel Fabrication Parts Customized |

||

Factory Customized Bending And Welding Stainless Steel Fabrication Sheet Metal Parts

![]()

|

Material

|

1) Aluminum: AL 6061-T6, 6063, 7075-T etc.

|

|

2) Stainless steel: 303,304,316L, 17-4(SUS630) etc.

|

|

|

3) Steel: 4140, Q235, Q345B,20#,45# etc.

|

|

|

4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc.

|

|

|

5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc.

|

|

|

6) Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc.

|

|

|

Finish

|

Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish.

|

|

Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing.

|

|

|

Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench).

|

|

|

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc.

|

|

|

Main Equipment

|

CNC Machining center(Milling), CNC Lathe, Grinding machine.

|

|

Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc.

|

|

|

Drawing format

|

STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples.

|

|

Tolerance

|

+/-0.01mm ~ +/-0.05mm

|

|

Surface roughness

|

Ra 0.1~3.2

|

|

Inspection

|

Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM.

|

|

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge.

|

|

|

Capacity

|

CNC turning work range: φ0.5mm-φ150mm*300mm.

|

|

CNC milling work range: 510mm*1020mm*500mm.

|

Product display

![]()

Quality Control

![]()

Surface Treatment

Galvanization: Coating the metal surface with a layer of zinc to prevent corrosion.

![]()

Application

Automotive Industry: Engine components, body structures, chassis parts, suspension systems, transmission systems

![]()

About us

Nanjing Pusher Machinery Co.,Ltd. is specializing in customized-made CNC machining and welding, casting, forging. With over 10 years’ experience in the field. Our Precision Machining, innovative, with an unique design and superior quality, are suitable for any kind of medical, automotive, consumer goods, aerospace, energy, and robotics. and will meet your needs.With a massive R&D environment, Pusher took advantage of market-leading technology and introduced various of advanced equipment to guarantee the rigorous quality in production.

![]()

Product Packaging

![]()

![]()

Certificates

![]()

FAQ

Q:If I need urgent delivery, can you help?

A:Of course! “Customer first” is our company philosophy. You need to tell us the delivery time when placing the order, and we will do our best to adjust the production schedule.