-

KamilGreat quality, competitive price and outstanding communication.

KamilGreat quality, competitive price and outstanding communication. -

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs.

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs. -

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

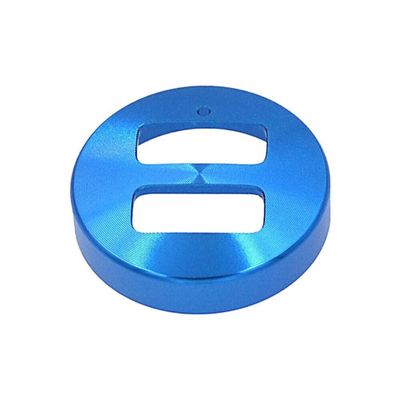

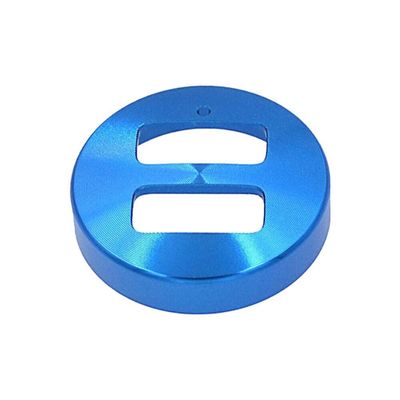

Anodizing Metal Parts Milling Turning Custom CNC Components for Industrial Equipment

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| QC | 100% Inspection | Model Number | Customized Cnc Parts |

|---|---|---|---|

| MOQ | 1 Piece | Size | Customer's 3D Drawing |

| Our Service | OEM ODM Customers'drawing | Material | Aluminum,Brass,Bronze,Stainless Steel,Customized |

| Highlight | Milling Turning CNC Components,Anodizing Metal Parts CNC Components,Industrial Equipment CNC Components |

||

Anodizing Metal Parts Milling Turning Custom CNC Components for Industrial Equipment

Products paramenters

| Material | Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc |

| Size or shape | According to customer drawings or requests |

| Service | Sheet Metal Fabrication / CNC Machining / Metal cabinets&enclosure&box / Laser Cutting Service / Steel Bracket / Stamping Parts, etc. |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/ Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| Tolerance | ±0.002 ~ ±0.005mm, 100% QC quality inspection before delivery, |

![]()

Surface treatment

Powder Coating: A dry finishing process where fine particles of pigment and resin are sprayed onto the surface of the part and then baked to form a durable coating. It provides excellent protection against corrosion, chemicals, and abrasion and is available in a wide range of colors and textures.

Plating: Including chrome plating, nickel plating, zinc plating, etc., it can improve the corrosion resistance, conductivity, and appearance of the parts.

![]()

Application

Automotive Industry: CNC machined parts are extensively used in automobiles for components such as engine parts, transmission systems, chassis components, interior fittings, and exterior body panels.

Medical Equipment: The medical equipment industry has strict requirements for precision and materials, with CNC machining used in the manufacturing of various medical devices, surgical tools, artificial joints, etc.

![]()

Quality Control

![]()

About PUSHER

Nanjing Pusher Machinery Co.,Ltd. is specializing in customized-made CNC machining and welding, casting, forging. With over 10 years’ experience in the field. Our Precision Machining, innovative, with an unique design and superior quality, are suitable for any kind of medical, automotive, consumer goods, aerospace, energy, and robotics. and will meet your needs.

With a massive R&D environment, Pusher took advantage of market-leading technology and introduced various of advanced equipment to guarantee the rigorous quality in production. At Pusher, innovation and new product development are common currency. We listen to our clients and we do not hesitate to create new products to satisfy their needs. With our high production capacity, we cater not only to users but also to machinery manufacturers.

![]()

Product packaging

![]()

![]()

Certification

![]()