-

KamilGreat quality, competitive price and outstanding communication.

KamilGreat quality, competitive price and outstanding communication. -

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs.

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs. -

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

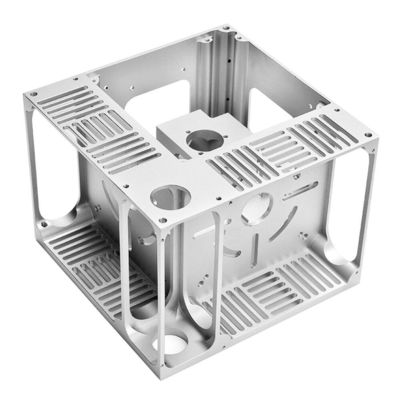

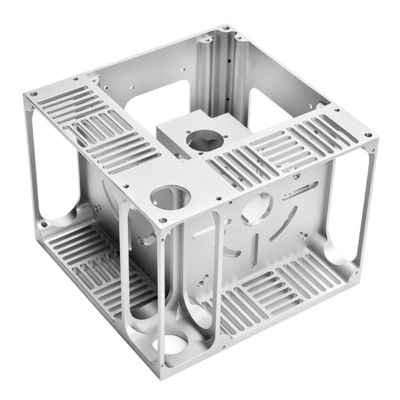

Accurate Tolerance Stainless Steel CNC Milling Parts For Custom Precision Machining

| Features | High Precision, Accurate Tolerance | Material | Steel |

|---|---|---|---|

| Application | Metal Processing Machinery Parts | Advantages | High Precision, Low Price |

| Specification | As Per DrawingS Or Samples | Finish | Cleaning, Anodizing, Electroplates, Powder Coat... |

| Highlight | Accurate Tolerance CNC Milling Parts,Accurate Tolerance stainless steel milling parts,stainless steel milling parts Custom |

||

Stainless Steel CNC Turning Milling Service Parts for OEM Custom Precision Machining

![]()

Product Paramenters

| Processing | CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

| Size | Customized |

| Technics | laser cut, bend, weld, stamp |

| Drawing Format | 3D/CAD/Dwg/IGS/STP |

| Materials | Stainless steel: SUS303, SUS304, SS316, SS316L etc. Aluminum: 2000 series, 6000 series, 7075, 5052, etc. Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing,Laser/Engrave etc. |

| Heat treatment | Annealing, Normalizing , Nitriding, Tempering , Carbonitriding |

| Tolerance | ±0.002 ~ ±0.005mm |

| Surface Roughness | Min Ra 0.1~3.2 |

| Inspection | In-house or third party, all the products are strictly inspected by skilled QC |

Product display

![]()

![]()

![]()

![]()

![]()

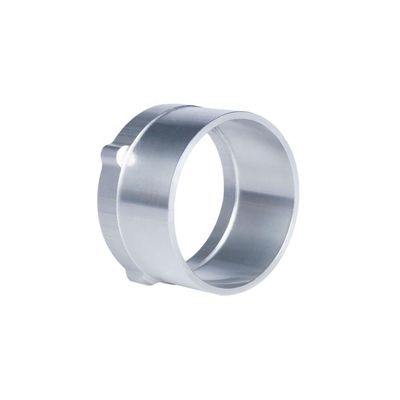

Surface Treatment

Plating: Coating the surface of the part with a layer of metal (such as chrome, nickel, or copper) to improve its appearance, corrosion resistance, and conductivity.

Polishing: Achieving a high gloss and smooth surface finish through mechanical grinding or chemical treatment, improving the appearance quality.

![]()

Application

Electronics Industry: CNC milling is utilized in the production of electronic enclosures, heat sinks, connectors, and other precision components for electronic devices.

Energy Sector: CNC milling parts are utilized in the energy sector for the production of components for renewable energy systems, power generation equipment, and oil and gas exploration equipment.

![]()

Shipping

![]()

About PUSHER

Nanjing Pusher Machinery Co., Ltd is specializing in customized-made CNC machining and welding, casting, forging.

Our products cover a wide range of industries including train & Railway, automobile & Truck, construction machinery, mining machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery, construction, valve and pumps, electric machine, hardware, power equipment and so on.

![]()

FAQ

Q: What can we do for you?

A:1) 100% local manufacturer

2) Best material selection

3) Best lead time and stable production

4) Rich experience on export business

5) Professional services

6) Quality control.