-

KamilGreat quality, competitive price and outstanding communication.

KamilGreat quality, competitive price and outstanding communication. -

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs.

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs. -

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

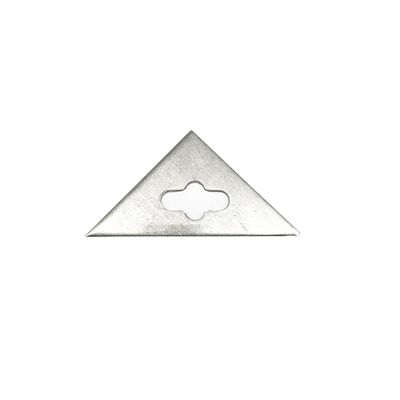

Customized Metal stamping parts Carbon Steel Heat treatment Aluminium for Engineering machinery part

| Name | Stamping Parts | Size | Customized Sizes |

|---|---|---|---|

| Surface Treatment | Painting\Powder Coating\Plating\Polishing | Advantage | OEM / ODM / Customized Service Provided |

| Material | Stainless Steel | Color | Customized Color |

| Highlight | Engineering machinery Metal stamping parts |

||

Customized Metal stamping parts Carbon Steel Heat treatment for Engineering machinery part

(1) The stamped parts have high dimensional accuracy.

(2) Stamping processing has good stability, and stamping parts from the same batch can be interchanged without affecting assembly and product performance.

(3) Since stamping parts are made of sheet metal, their surface quality is good, which provides convenient conditions for subsequent surface treatment processes (such as electroplating and spray painting).

(4) Stamping processing can obtain parts with high strength, high rigidity and light weight.

(5) The cost of stamping parts produced in batches with molds is low.

(6) Stamping can produce parts with complex shapes that are difficult to process with other metal processing methods.

A:Depending on the number of products and the ease of processing, we generally speed up production when we receive an order