All Products

-

KamilGreat quality, competitive price and outstanding communication.

KamilGreat quality, competitive price and outstanding communication. -

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs.

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs. -

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

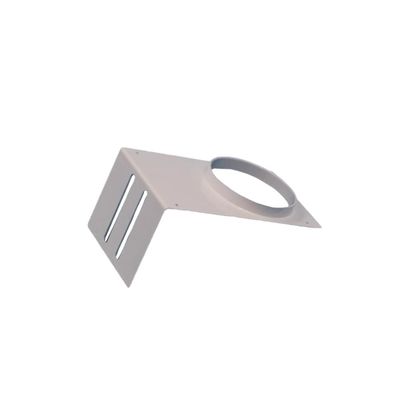

100% Full Inspection Custom Stamping Parts for Electrical Auto Sheet Metal Stamping

Product Details

| Specification | Customized According To Your Drawings | Materials | Steel, Stainless Steel, Aluminium, Brass |

|---|---|---|---|

| Surface Treatment | Powder Coating, Electro Galvanizing, Hot Galvanizing | Process | Blanking,punching,piercing,forming |

| Service | Customized OEM Metal Stamping | Sample | Avaliable |

| Highlight | 100% Full Inspection Stamping Parts,Custom Stamping Parts,Electrical Auto Sheet Metal Stamping |

||

Product Description

100% Full Inspection Custom Stamping Parts for Electrical Auto Sheet Metal Stamping

What's metal stamping?

Stamping is a forming processing method that relies on presses and molds to apply external force to plates, strips, pipes and profiles to cause plastic deformation or separation, thereby obtaining workpieces (stamping parts) of the required shape and size. 60 to 70% of the world's steel products are plates, most of which are stamped into finished products.

The body, chassis, fuel tank, radiator fins of automobiles, boiler drums, container casings, iron core silicon steel sheets of motors and electrical appliances, etc. are all stamped. There are also a large number of stamped parts in products such as instruments and meters, household appliances, bicycles, office machinery, and living utensils.

Stamping equipment

Product Paramenters

Product Display

Please contact us for more requirements

Why choose Pusher?

Material:we use the top A level quality which is Specified and traceable .We don't choose other supplier's materials just because they are cheaper.

Process: CNC milling equipment is used for processing to make the surface smooth.

Full inspections of Key dimensions: tolerance size ±0.01. Complete sample inspection.

Samples we can provide to you faster.

Packing:we can provide to you with pearl wool to guarantee the goods safer and not get scratched.

Product Packaging

Applications

Certifications

FAQ

Q: What is the lead time for mass production?

A: It depends on the order quantity and when you place the order.

Recommended Products