-

KamilGreat quality, competitive price and outstanding communication.

KamilGreat quality, competitive price and outstanding communication. -

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs.

RobertThank you very much for the kind words and gestures! I appreciate it. I will continue to reach out to you and your company first for future manufacturing needs. -

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

KevinI want to thank you guys for the guys they’re really nice and helpful for us.

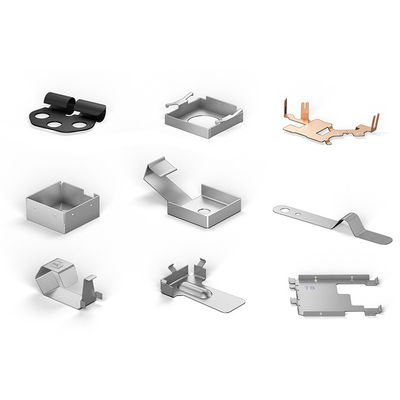

OEM Laser Cutting and Logo Fabrication Services for Custom Sheet Metal Stamping Parts

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Fabrication Stamping Part | Surface Treatment | Mirror Polishing, Anodize,Electroplating,Oxide,Sandblasting |

|---|---|---|---|

| QC Control | 100% QC Steps Inspection | Our Service | Custom Machining CNC Services |

| Material | Stainless Steel, Brass, Copper, Aluminum, Carbon Steel, Alloy Steel | Tolerance | ±0.01-0.05mm |

| Highlight | Custom Sheet Metal Stamping Parts,OEM Sheet Metal Stamping Parts |

||

OEM Laser Cutting and Logo Fabrication Services for Custom Sheet Metal Stamping Parts

The body, chassis, fuel tank, radiator fins of automobiles, boiler drums, container casings, iron core silicon steel sheets of motors and electrical appliances, etc. are all stamped. There are also a large number of stamped parts in products such as instruments and meters, household appliances, bicycles, office machinery, and living utensils.

(1) The stamped parts have high dimensional accuracy.

(2) Stamping processing has good stability, and stamping parts from the same batch can be interchanged without affecting assembly and product performance.

(3) Since stamping parts are made of sheet metal, their surface quality is good, which provides convenient conditions for subsequent surface treatment processes (such as electroplating and spray painting).

(4) Stamping processing can obtain parts with high strength, high rigidity and light weight.

(5) The cost of stamping parts produced in batches with molds is low.

(6) Stamping can produce parts with complex shapes that are difficult to process with other metal processing methods.

Sandblasting: High-pressure airflow is used to propel sand particles onto metal surfaces to improve surface texture and increase roughness.

Shot blasting: Similar to sandblasting, but using metal particles, it can remove surface oxidation and impurities, improving coating adhesion.

Material:we use the top A level quality which is Specified and traceable .We don't choose other supplier's materials just because they are cheaper.

Process: CNC milling equipment is used for processing to make the surface smooth.

Full inspections of Key dimensions: tolerance size ±0.01. Complete sample inspection.

Samples we can provide to you faster.

Packing:we can provide to you with pearl wool to guarantee the goods safer and not get scratched.

Q:Can you make machining parts based on our samples?

A:Yes, we can make measurements based on your samples to make drawings for machining parts.